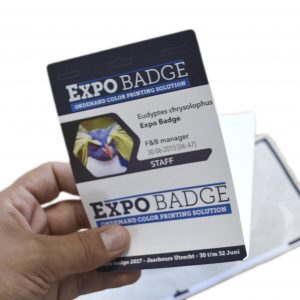

Print tickets and event badges on location live , or ExpoBadging. The arrival of ExpoBadge products makes it possible from now on. We leave the printing to the Epson TM-C3500 ColorWorks color label printer.

The purpose of ExpoBadging

ExpoBadges originated from the idea of developing a product that would offer “live and full-color” printing, of congress, event and trade show badges, multiple advantages over static pre-printed materials.

Benefits include:

- Never again missing badges for unexpected visitors;

- Savings by not having to throw away expensive unused pre-printed media;

- Value increase badge advertising by linking the ads to the interest per visitor;

- Reducing personnel costs;

- Optimal flow through fast issuance;

And even more benefits that can vary per situation.

Unexpected visitor

Everyone in the eventing knows the problem, all badges are ready in alphabet and the visitors come in. Then suddenly there is an unexpected VIP there for which there is no badge, what now? With ExpoBadging you print an extra badge live and simply. The VIP’s hardly notice that he / she is not expected and then wears a k (l) eurige badge.

Unnecessary waste

The lack of badges is a “no go” for organizers. If 10,000 visitors are expected, 12,000 badges will soon be pre-printed, most of which will end up in the waste container. With ExpoBadging this is now a thing of the past. Namely, the badge material enters the printer blank and the unused badge material, instead of a permanent visit to the waste container, is simply used for the next event. Friendly solution for the environment and your wallet.

Increased ad value

Advertisements on pre-printed badges usually do not match the interests of the visitor.

By indicating in advance, when registering in the software, what the need and interest of the visitor is, targeted advertising is possible. This significantly increases the value of the ad.

Reduce personnel costs

Firstly, people don’t like to wait, and secondly, an optimal flow of visitors is highly desirable. The image of hostesses (m / f) looking in alphabet trays and separate queues with visitors, such as VIPs or Press, is outdated. With ExpoBadging, the hostess quickly prints the visitor’s badge “live” without an alphabet tray and separate queues. It may be clear that fewer hosts are needed, which means a considerable staff saving. In fact, we are seeing more and more “columns” where the visitor purchases his / her badge and only one host supports multiple rows.

Faster flow

Get rid of the alphabet trays, printing works faster and the Epson TM-C3500 works even faster than a laser printer. Avoid long queues and speed up the flow … that will make everyone happy.

The printer

The ExpoBadge products are specially developed for use in an Epson ColorWorks TM-C3500.

Mobility

The Epson TM-C3500 is a compact printer of only 12 kg and therefore easy to take with you on location. The compact size of the TM-C3500 makes it easy to install in columns and other mobile solutions.

Cost efficient

The DURABrite ™ Ultra ink technology of the TM-C3500 delivers high color yield and is therefore very economical in consumption.

User-friendly and reliable

At the entrance you will usually not find IT people but hosts who are focused on receiving guests. In order for these hosts to be able to do their work without problems, they must be able to count on working with user-friendly and reliable equipment.

Ink cartridges

Anyone can replace an ink cartridge with the Epson TM-C3500. With many bells and whistles, the printer indicates that a cartridge is empty. On the display you can read which cartridge needs to be replaced. Roll up the sleeves and get started … open the front cover, then press on the empty cartridge that you can use to unlock it and take it out, then press the new cartridge securely in the same place, close the cover, just roll off the sleeves because you can continue.

Load badges

A stack of blank badges is called a stack. And how do you load a new stack into the printer? It couldn’t be simpler than this, slide the first badge of the new stack “face-up” on the back until the printer picks it up from you. The printer will position the badge and possibly cut it off, after which it will be possible to print again.

Moisture and scratch resistant

The Epson DURABrite ™ Ultra inks, in combination with the right media, are moisture and scratch resistant.

Available ExpoBadges

The range of ExpoBadge products is expanding more and more, tickets and Butterfly badges are now also available. The most used ExpoBadge products fall under the ExpoBadge 260 series. This series has two types of material and multiple formats.

The material

The Butterfly badges are produced from two types of material. These materials seem the same but differ “under the hood”. Both materials have their own advantages and disadvantages.

Standard ExpoBadge 260

For the standard ExpoBadge 260 series, thick, almost thin cardboard, paper is used. The paper has a matte appearance and ensures that the ink is absorbed quickly. These badges are often used for 1-day events.

Tear-resistant ExpoBadge 260, the T version

The ExpoBadge 260 is also available in a tear-resistant “T” variant, which stands for tear resistant .

This “T” material contains a thin plastic layer, making cracking virtually impossible. Suitable for multi-day events. This material is not resistant to moisture, there may be a voltage difference between the plastic and paper, which does not promote the appearance of the badge.

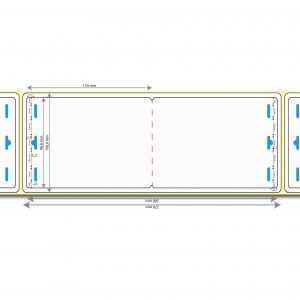

Sizes, versions and possibilities

We do not include all new badge formats in the standard range.

Below a selection from the assortment where we place the comment: call us for a quote if the requested size is not listed.

- ExpoBadge 260 Badge format 96.5 x 134mm

- ExpoBadge 260T Badge format 96.5 x 134mm, tear-resistant

- ExpoBadge 260S Badge format 96.5 x 82mm

- ExpoBadge 260TS Badge format 96.5 x 82mm, tear-resistant

- ExpoBadge 260+ Badge format 96.5 x 134 mm + 2 vouchers of 105 x 50 mm

- ExpoBadge 260S RFID Badge format 96.5 x 82mm including RFID (no stock product)

ExpoBadge with RFID

Can you also supply Butterfly badges with an RFID chip in the badge? In the meantime our answer is short but powerful: yes we can. The road to the realization of an RFID chip in terms of; linked application to the RFID chip, UHF frequencies, exchange of contact details, the reading distance, antenna and several other factors is less short. The Butterfly badges with RFID are produced specifically for the application.

The story behind ExpoBadge

The development of the first ExpoBadge started for the specific target group of event organizers. It is now a completely new line of products from Diamond labels. A product line with specially designed and developed materials that is aimed at this target group. It should have been that way … shortly after the start of our partnership with Epson for the ColorWorks printers, we received the first question from an event organizer. After an in-depth investigation, we soon had a goal in mind that proved to be as simple as new, a solution had to be found for “live” printing, or ExpoBadging, of access passes, tickets and badges. A solution that increases flexibility, reduces personnel costs and speeds up access.

The development of the ExpoBadge

Every development of a new product starts with market research. After a number of phone calls it soon became clear that the market was eager to find a solution for the cost-efficient and simple “live” color printing of badges. Previously there was only one solution and it consisted of dragging heavy and bulky printers. Often they were laser printers that needed a lot of power and if they did not print for a while they first had to warm up again. In short, too slow and awkward with transport.

The first steps

The first steps were taken in 2014, after which the first ExpoBadge products soon became available. The first product was actually not a badge but a ticket. A ticket with an extra perforation to easily tear off a small part as a voucher. The voucher was then torn off at the entrance or used as a voucher for a free cup of coffee or something.

Requirements for a badge

The Badges turned out to be a bigger challenge. There are a lot of hooks and eyes on a good badge. Below a number of requirements that a badge had to meet:

- the badge must be able to be printed on both sides;

- the badge must be made of sturdy material;

- the badge must be easy to fold after printing;

- the print must be scratch and moisture resistant;

- the ink must be immediately dry (folding should not give dirty fingers);

- the color yield must be optimal.

The Butterfly badge

The requirement for a double-sided printed badge resulted in the so-called Butterfly form . A butterfly badge is printed in its entirety and then folded in half so that you end up with a double-sided printed badge.

The ability to print the badge from edge to edge, or full bleed, or descending, is increasingly becoming a requirement than a wish.

Although full-bleed printing is possible with the Epson TM-C3500, that would cause unwanted ink on the backing paper and therefore result in stains. The solution is in the following …

The backing paper of label material (the backing) is a silicone paper which ensures that the glue does not adhere and the label comes off easily. But … silicone also ensures that ink does not dry, so printing on backing paper would cause dirty fingers when the badge is removed.

This problem has been solved by a “label in label” method which you can print the badge from edge to edge without any problems with your fingers.

The basic material

Tickets

The ticket material is relatively simple. This was already an existing product that was sold for other ticket solutions. So only the shape and dimensions were important for this.

This ticket material was rolled out under the name ExpoBadge as “ EasyBadge “, a ticket with rounded corners for a slip-in cover. The basic material for this is the DIA160gr, a 160 gram per m2 ticket paper with a special coating for the Epson ColorWorks printers.

First sample production of Butterfly badges.

The search for good material for the Butterfly badges was a completely different story. In the course of 2015, a number of sample productions were made from different materials. The first real Butterfly badge that was produced under the name ExpoBadge was made of tear-resistant glossy paper. Unfortunately, it never got any further than sample production because ink dries less quickly on a glossy coating, which only increases the chance of stains.

ExpoBadge PRO

A few weeks later, the first sample production took place on tear-resistant matte paper. The ink was dry immediately after printing, so we had the solution against dirty fingers and stains. Unfortunately, the stiffness of the material turned out not to be optimal. To improve this, it was decided to cut the backing paper so that it is folded into the badge. This also solved this problem and the end product was launched under the ExpoBadge PRO. The first reactions to this were mixed, where one customer thought this solution was great, especially on the basis of the extra options, while the other customer did not find the product “stiff” enough and difficult to fold neatly. Because there was no longer any possibility to improve the product in 2015, the product was nevertheless marketed to customers who were content with a solution like this.

ExpoBadge 260

Happy with the satisfied customers of the ExpoBadge PRO, we ourselves were far from satisfied with the product. It was not good enough for many customers and we felt we could do better. We continued to be concerned that the product was not yet finished, was not complete enough and therefore the ExpoBadge series was also incomplete.

Breakthrough

Until almost 2 years after the launch of the ExpoBadge PRO, little progress had been made, despite frantic attempts to achieve better material. The cover came in 2017 …

At the beginning of 2017 the first samples of material specially developed for us, Smart2B, arrived. Two variants, standard matte paper, and tear-resistant material. Both extra thick with the right “stiffness” but also not too thick for the printer and provided with a special coating specifically for Epson’s inks so that it dries quickly. After the first test deliveries to customers, it soon becomes apparent … this is it all!

Sizes and shapes

In order to be able to offer a thoughtful and complete line of badges, careful consideration has been given to the standard sizes. Through feedback from a number of partners with the necessary know-how we finally started with two sizes, namely 96.5 x 82 mm and 96.5 x 134 mm. Both have 2 slotted holes on the sides, and 1 slotted hole with hanging eye in the middle.

The event badges have now been launched under the name ExpoBadge 260.

The reactions to the new ExpoBadge series are simply fantastic. We, too, are satisfied and proud and, with the ExpoBadge 260 series, finally dare to say that there is a fully-fledged product on the market for live printing of badges and tickets and also in color!

At the moment the requests are rolling in with us for round shapes and different sizes, for example the request for an ExpoBadge 260 with 2 vouchers of 50mm attached.

And, meanwhile, for a worldwide organization from the medical world, a custom-made product has been delivered with a separate part for the visitor’s personal program attached to the badge.

Ivar van der MolenFor us it is clear, there is still a lot of challenge in the world of ExpoBadging! [/ blockquote]